Application

Home > Application

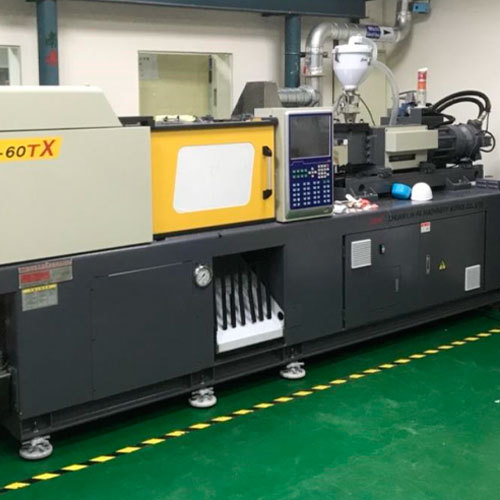

In order to produce high precision plastic products, the injection molding machine develops towards the electronic direction. Electronic injection molding machine than the past hydraulic injection molding machine more environmental protection, more energy saving, in today's environmental protection era, the demand for electronic injection molding machine has increased.

With this power, these components are expected to remain highly reliable in the face of unprecedented adverse operating conditions. The high bearing capacity of NSK products is an important part of mechanical transmission parts (injection shaft, mould shaft, ejection shaft, extrusion shaft, which can be used as plastic parts).

The injection molding machine with NSK products also includes special groove design measures for maximum ball diameter and high load by optimizing the circulation circuit configuration, which greatly improves the resistance load performance of "special ball screw for high load drive" and has high bearing capacity. The ball diameter of the special ball screw for load driving realizes the "thrust angular contact ball bearing" with high bearing capacity and the "roller guide" with NSK cutting-edge technology featuring high bearing capacity, high rigidity and environmental protection.

As the world's only fully developed and fully supplied mechanical parts manufacturer, NSK is committed to contribute to the future development of injection molding machines.

NSK's performance and innovative technology

Grease seal special ball screw A1 series for high speed and high load

In the electromechanical dynamic process of injection molding, the rated load and maximum allowable load of the HTF series of high load driven ball screw developed by NSK company in 1996 are greatly increased. HTF series thrust angular contact ball bearings were launched in 2000. This series is to realize high-speed running of roller bearing and improve the assembly performance of bearing. In 2013, NSK's latest TAC03 series began investing in the market. Accordingly, the angular contact ball bearing was updated.

In the increasingly severe situation of environmental protection, NSK company in 2007 launched the "high oil seal type high speed, high load special ball screw A1 series", to further improve the environment, reduce the use of lubricating oil to make a contribution.