Linear sliders can be divided into: roller linear guides, cylindrical linear guides, and ball linear guides. They are used to support and guide moving parts and make reciprocating linear motion in a given direction. Depending on the nature of the friction, linear motion guides can be classified into sliding friction guides, rolling friction guides, elastic friction guides, and fluid friction guides.

definition

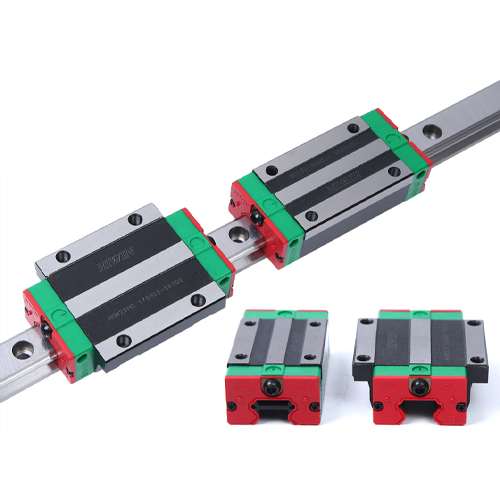

Linear guides, also known as line rails, slide rails, linear guides, and linear slide rails, are used for linear reciprocating applications and can withstand a certain amount of torque to achieve high-precision linear motion under high load conditions. Linear guides are called in the mainland. Taiwan is generally called linear guides and linear slides.

classification

It is divided into square ball linear guide, double shaft core roller linear guide, single axis core linear guide.

effect

The function of the linear guide motion is to support and guide the moving parts to make a reciprocating linear motion in a given direction. Depending on the nature of the friction, linear motion guides can be classified into sliding friction guides, rolling friction guides, elastic friction guides, and fluid friction guides. Linear bearings are mainly used in automation machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear bearings and linear shafts are used together. Linear guides are mainly used on mechanical structures with high precision requirements. There is no intermediate medium between the moving parts and fixed elements of the linear guides, and rolling steel balls are used.

working principle

It can be understood as a kind of rolling guide, which is an infinite rolling cycle between the steel ball and the guide rail, so that the load platform can easily move linearly along the guide rail with high precision, and the friction coefficient is reduced to the conventional conventional sliding guide. One-fifth of the time, it is easy to achieve high positioning accuracy. The design of the end block between the slider and the guide rail enables the linear guide to bear the load in all directions, such as up, down, left and right. The patented reflow system and the simplified structural design make the linear guide of HIWIN smoother and less noisy.

Slider - Turns the motion from a curve to a straight line. The new rail system allows the machine to achieve fast traverse speeds. At the same spindle speed, fast traverse is a linear guide. Linear guides, like flat guides, have two basic components; one for the fixed component and the other for the moving component. Since linear guides are standard components, for machine tool builders. The only thing left to do is to machine the parallelism of the plane of the mounting rail and the alignment rail. Of course, in order to ensure the accuracy of the machine tool, a small amount of scraping of the bed or column is essential, and in most cases, the installation is relatively simple. The guide rail as a guide is hardened steel, which is finely ground and placed on the mounting plane. Compared with the planar guide rail, the geometry of the cross section of the linear guide is more complicated than that of the flat guide. The reason for the complexity is that the groove needs to be machined on the guide rail to facilitate the movement of the sliding element. The shape and number of the groove depend on the machine tool to be completed. The function. For example: a rail system that withstands both linear forces and subversive moments, compared to rails that only accept linear forces. The design is very different.

The basic function of the fixed element (rail) of the linear guide system is like a bearing ring, a bracket for mounting a steel ball, and the shape is a "v" shape. The bracket wraps around the top and sides of the rail. In order to support the working parts of the machine tool, a set of linear guides has at least four brackets. Used to support large work pieces, the number of brackets can be more than four.

When the working part of the machine tool moves, the steel ball circulates in the groove of the bracket, and the wear amount of the bracket is distributed to each steel ball, thereby extending the service life of the linear guide. In order to eliminate the gap between the bracket and the guide rail, the preloading can improve the stability of the rail system and obtain the preload. An oversized steel ball is placed between the rail and the bracket. The steel ball has a diameter tolerance of ±20 μm, and the steel balls are sorted and classified into 0.5 μm increments, and are respectively mounted on the guide rails. The magnitude of the preload is determined by the force acting on the steel balls. If the force acting on the steel ball is too large and the preloading time is too long, resulting in an increase in the kinematic resistance of the bracket, there will be a balance problem; in order to improve the sensitivity of the system and reduce the motion resistance, the preload is accordingly reduced. In order to improve the accuracy of motion and the accuracy of accuracy, it is required to have sufficient pre-added negative numbers, which is two aspects of contradiction.

When the working time is too long, the steel ball begins to wear, and the preload applied to the steel ball begins to weaken, resulting in a decrease in the movement accuracy of the working parts of the machine tool. If you want to maintain the initial accuracy, you must replace the rail bracket or even replace the rail. If the rail system is preloaded. The accuracy of the system has been lost, the only way is to replace the rolling elements.

The design of the rail system strives to maximize the contact area between the fixed component and the moving component. This not only improves the load carrying capacity of the system, but also the system can withstand the impact force generated by intermittent cutting or gravity cutting, spreading the force widely and expanding the bearing. The area of force. In order to achieve this, the groove system has a variety of groove shapes, two representative ones, one called Gothic (pointed arch), the shape is a semicircular extension, the contact point is the apex; the other It is a circular arc and can play the same role. Regardless of the type of construction, there is only one purpose, and it is intended to bring more rolling steel ball radii into contact with the guide rail (fixing element). The factor that determines the performance characteristics of the system is how the rolling elements come into contact with the rails, which is the key to the problem.

Application field

1. Linear guides are mainly used in automation machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guides and linear axes are used together.

2. The linear guide rail is mainly used on the mechanical structure with higher precision requirements. The intermediate medium is not used between the moving component and the fixed component of the linear guide rail, and the rolling steel ball is used. Because the rolling steel ball is suitable for high-speed movement, small friction coefficient and high sensitivity, it can meet the working requirements of moving parts, such as tool holders and carriages of machine tools. If the force acting on the steel ball is too large, the steel ball is subjected to the preloading time for too long, resulting in an increase in the kinematic resistance of the bracket.

Use attention

Linear guides are precision parts, so they require a very careful attitude when used. Even if high-performance linear guides are used, if they are not used properly, the expected performance will not be achieved, and the linear guides will be easily damaged. Therefore, the following matters should be noted when using linear guides:

Prevent corrosion

When taking the linear guide directly by hand, wash off the sweat on your hands and apply high-quality mineral oil before handling. Pay special attention to rust prevention during the rainy season and summer.

Keep the environment clean

Keeping the linear guide and its surroundings clean Even if tiny dust that is invisible to the naked eye enters the guide rail, it will increase the wear, vibration and noise of the guide rail.