Introduction

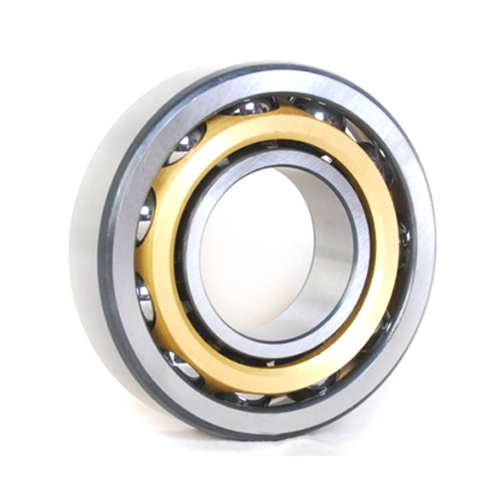

Angular Contact Ball Bearings can withstand both radial and axial loads. Can work at higher speeds. The larger the contact angle, the higher the axial load carrying capacity. The contact angle is the angle between the line connecting the contact point of the ball and the raceway in the radial plane and the vertical line of the bearing axis. High precision and high speed bearings typically take a 15 degree contact angle. Under the axial force, the contact angle will increase

Type editing

The line connecting the ball bearing ball to the contact point of the inner and outer rings is at an angle to the radial direction. The contact angle is generally divided into 15°, 30°, and 40°, which are represented by the letters C, A, and B, respectively. NSK specially produces such bearings with a contact angle of 25°, which is indicated by A5.

Angular contact ball bearings are mainly subjected to large one-way axial loads, and the greater the contact angle, the greater the load bearing capacity. The cage material is steel plate, brass or engineering plastic. The forming method is stamping or turning, depending on the bearing form or the conditions of use. Other combinations of angular contact ball bearings, double row angular contact ball bearings and four-point contact ball bearings.

The angular contact ball bearing models are divided into: α=15° angular contact ball bearings (70000C type); α=25° angular contact ball bearings (70000AC type); α=40° angular contact ball bearings (70000B type) Back-to-back paired double angular contact ball bearings [70000C (AC, B) / DB type]; face-to-face paired double angular contact ball bearings [70000C (AC, B) / DF type]; series paired double angle Contact ball bearings [70000C (AC, B) / DT type]; double row angular contact ball bearings with ball gap (model 00000); double row angular contact ball bearings without ball gap (type 00000A); no ball Double-row angular contact ball bearings with a dust cover on one side (Model 00000A-Z); double row angular contact ball bearings with no ball cover and double-sided dust cover (Model 00000A-2Z); no ball gap Double row angular contact ball bearing with sealing ring on one side (00000ARS type); double row angular contact ball bearing with double sealing groove on both sides (00000A-2RS type); four point angular contact ball bearing (QJ0000 type) ), counting 13 kinds.

l Single column: 78XX, 79XX, 70XX, 72XX, 73XX, 74XX

2 Mini: 70X

3 double columns: 52XX, 53XX, 32XX, 33XX, LD57, LD58

4 Four-point contact: QJ2XX, QJ3XX

concept

Single row angular contact ball bearings can only withstand axial loads in one direction and will cause additional axial forces when subjected to radial loads. And can only limit the axial displacement of the shaft or housing in one direction. Angular contact ball bearings have a contact angle of 40 degrees and can withstand large axial loads. Angular contact ball bearings are non-separable designs with different shoulder heights on the sides of the inner and outer rings. In order to increase the bearing capacity of the bearing, the shoulder on one side is machined lower, so that the bearing can be loaded with more steel balls.

Double row angular contact ball bearings can withstand large radial loads and mainly combine radial and axial load and moment loads, limiting axial displacement of both sides of the shaft. Mainly used to limit the axial displacement of the shaft and the shell. The tiltability between the inner and outer rings of the double row angular contact ball bearing is limited. The allowable tilt angle depends on the internal clearance of the bearing, the bearing size, the internal design and the action. The force and moment on the bearing, and the maximum allowable tilt angle should ensure that there is no excessive additional stress in the bearing. If there is a tilt angle between the inner and outer rings of the bearing, it will affect the life of the bearing, and at the same time, the bearing running accuracy will decrease and the running noise will increase. Double row angular contact ball bearings typically use a nylon cage or a brass solid cage. When installing double row angular contact ball bearings, it should be noted that although the bearing can bear the bidirectional axial load, if there is a ball gap on one side, care should be taken not to let the main axial load pass through the notched side groove. When using the bearing, care should be taken to apply the main load to the side raceway without the ball gap.

If it is installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces the wide end faces, and the narrow end faces the narrow end faces. This avoids the need to cause additional axial forces and limits the shaft or housing to axial play in both directions.

Because the inner and outer races of the raceway can be displaced relative to each other on the horizontal axis, they can simultaneously withstand radial and axial loads—combined loads (single row angular contact ball bearings can only withstand uniaxial axial loads, so it is common Installed in pairs).

The angular contact ball bearings are mostly manufactured by foreign bearing manufacturers, and more domestic applications are applied to imported equipment such as angular contact ball bearings 3204RS, etc.

The narrow side is outside, the wide side is inside, the other wide side is inside, and the narrow side is outside, which is back-to-back contact.

Angular contact ball bearing accuracy grades include dimensional tolerances and rotational accuracy. The accuracy is expressed from low to high as P0 (normal), P6 (P6X), P5, P4, and P2. In addition, European and American brands also use P3, P7, and P9 to indicate the accuracy level, P3 is equivalent to the P6 level of the ISO and JIS standards, P7 is equivalent to the P4 level, and P9 is equivalent to the P2 level.

The main purpose

Single row angular contact ball bearings: machine tool spindles, high frequency motors, gas turbines, centrifugal separators, small car front wheels, differential pinion shafts, booster pumps, drilling platforms, food machinery, indexing heads, repair welding machines, Low noise cooling tower, electromechanical equipment, painting equipment, machine slot plate, arc welder

Double row angular contact ball bearings: oil pumps, Roots blowers, air compressors, various transmissions, fuel injection pumps, printing machinery, planetary reducers, extraction equipment, cycloid reducers, food packaging machinery, electric welding machines, electric soldering irons, Square box, gravity spray gun, stripping machine, semi-axle, inspection and analysis equipment, fine chemical machinery

Suffix definition

B: Modified internal structure

MP: Machined window brass cage

TVP: Glass fiber reinforced nylon cage

UA: Universal structural design for pairs of mounted bearings, small axial clearance bearing sets

UO: universal structural design of pairs of mounted bearings, zero axial clearance bearing set

DA: double inner ring (double row angular contact ball bearing)

TVH: Glass fiber reinforced polyamide cage, steel ball guide